Inserts for Plastic

Reinforce Your Plastic Assemblies with PENCOM’s Durable Inserts for Automotive, Electronics, and More

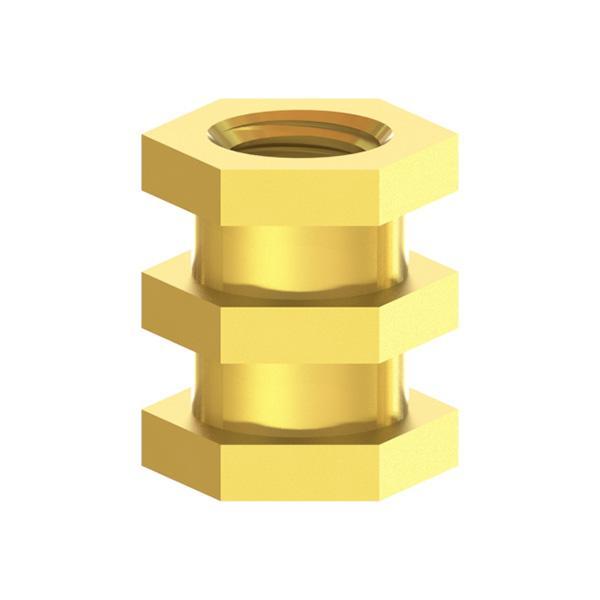

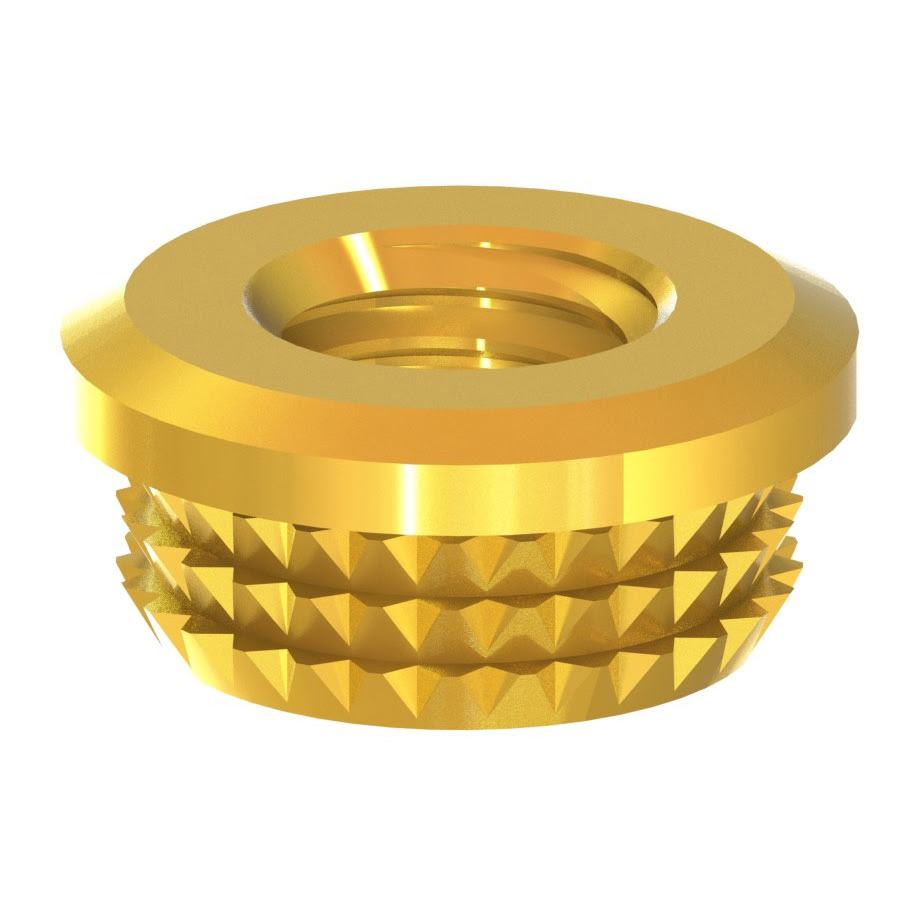

Inserts provide sturdy, reusable threads in plastic materials. They help eliminate creep and maintain integrity of tensioned joints. PENCOM’s inserts are available in either brass or stainless steel, and are suitable for a wide variety of installation methods and plastic material types. Inserts are commonly used in automotive, electronic, and communications equipment, as well as consumer product applications. Additional features include headed, studded, and thread locking abilities depending on performance needs. PENCOM also offers custom and modified sizes for customers looking to fit more specific needs. Contact us for more information.

Installation Materials

Amorphous Thermoplastics

- PC (Polycarbonate)

- Acrylic

- PETG (Polyethylene Terephthalate Glycol)

- ABS (Acrylonitrile Butadiene Styrene)

- Polysulfone

Thermoplastics – Soft

- HDPE (High-density Polyethylene)

- PE (Polyethylene)

- PP (Polypropylene)

Thermoplastics – Medium

- ABS (Acrylonitrile Butadiene Styrene)

- Nylon (Polyamide)

- POM (Acetal)

- PVC (Polyvinyl Chloride)

Thermoplastics – Hard

- Filled Nylon (Filled Polyamide)

- PBT (Polybutylene Terephthalate)

- PC/ABS Blend (Polycarbonate/ Acrylonitrile Butadiene Styrene)

- PPS (Polyphenlyene Sulfied)

Thermoplastic Foams

- PP (Polypropylene)

- PE (Polyethylene)

- Polystyrene

- PC (Polycarbonate)

- Polyvinyl Chloride

- Polylactic Acid

Thermosetting Polyester

- BMC (Bulk Molding Compound)

- DMC (Dough Molding Compound)

- SMC (Sheet Molding Compound)

Thermosetting Foam

- PU (Polyurethane)

- PF (Phenol-formaldehyde)

- UF (Urea-formaldehyde)

Thermosetting – Other

- Phenolic

- Ureas

- Tufnol

- Rigid polyurethane

- Epoxy resins

- Vinyl esthers