General

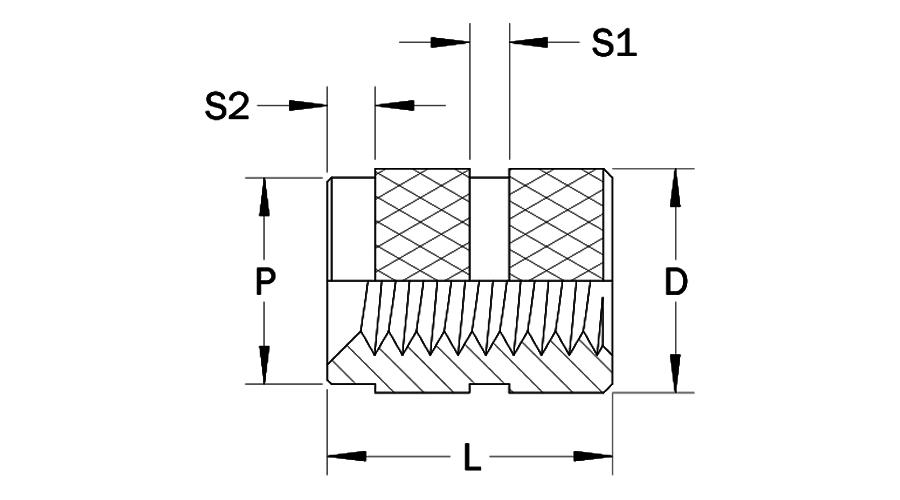

| Insert Thread | Insert Thread Code | L Insert Length ±.005 | Insert Length Code | D Stock Dia. Before Knurl | P End Diameter ±.005 | S1 | S2 | Thread Minor Diameter |

|---|---|---|---|---|---|---|---|---|

| 0-80 | 080 | .125 | 125 | .109 | .078 | .030 | .030 | .0475 -.0510 |

| 2-56 | 256 | .125 | 125 | .156 | .142 | .030 | .030 | .0670-.0737 |

| 4-40 | 440 | .188 | 188 | .188 | .171 | .030 | .030 | .0860-.0939 |

| 6-32 | 632 | .219 | 219 | .219 | .202 | .030 | .060 | .105 -.114 |

| 8-32 | 832 | .250 | 250 | .250 | .226 | .050 | .060 | .131-.139 |

| 10-24 | 1024 | .281 | 281 | .281 | .259 | .050 | .060 | .146 -.156 |

| 10-32 | 1032 | .281 | 281 | .281 | .259 | .050 | .060 | .157-.164 |

| 1/4-20 | 2520 | .375 | 375 | .344 | .321 | .060 | .090 | .197-.207 |

| 1/4-28 | 2528 | .375 | 375 | .344 | .321 | .060 | .090 | .212-.220 |

| 5/16-18 | 3118 | .469 | 469 | .437 | .404 | .080 | .090 | .260-.265 |

| 3/8-16 | 3716 | .562 | 562 | .500 | .466 | .090 | .090 | .309-.321 |

| Insert Thread Code | Host Material | Pull-out (lbs) | Torque-out (in-lbs) |

|---|---|---|---|

| 080 256 | ABS | 96-104 | 5.2- 5.6 |

| Polycarbonate | 106-115 | 5.6- 6.0 | |

| 440 | ABS | 166-175 | 5.5-6.0 |

| Polycarbonate | 173-186 | 6.2-6.9 | |

| 632 | ABS | 290-298 | 7.5-8.0 |

| Polycarbonate | 302-318 | 8.5-9.0 | |

| 832 | ABS | 368-370 | 13.6-14.0 |

| Polycarbonate | 372-382 | 14.7-16.0 | |

| 1024 1032 | ABS | 432-444 | 50-55 |

| Polycarbonate | 445-454 | 52-57 | |

| 2520 2528 | ABS | 620-635 | 75-70 |

| Polycarbonate | 635-650 | 98-103 |