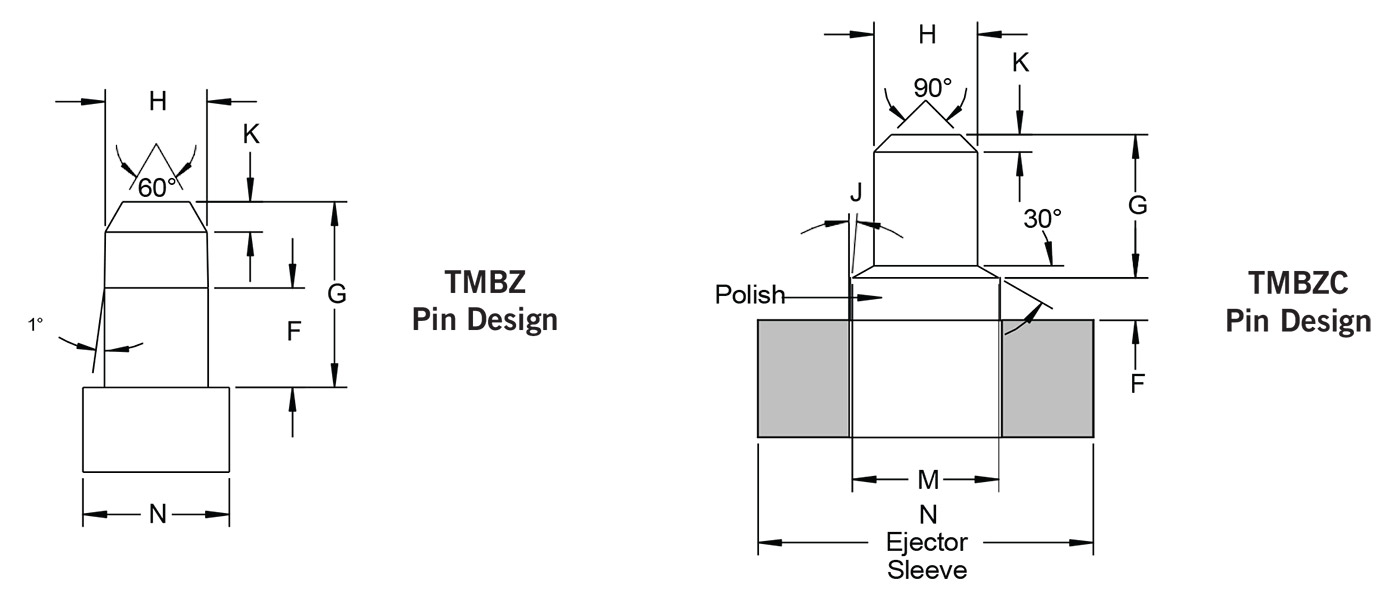

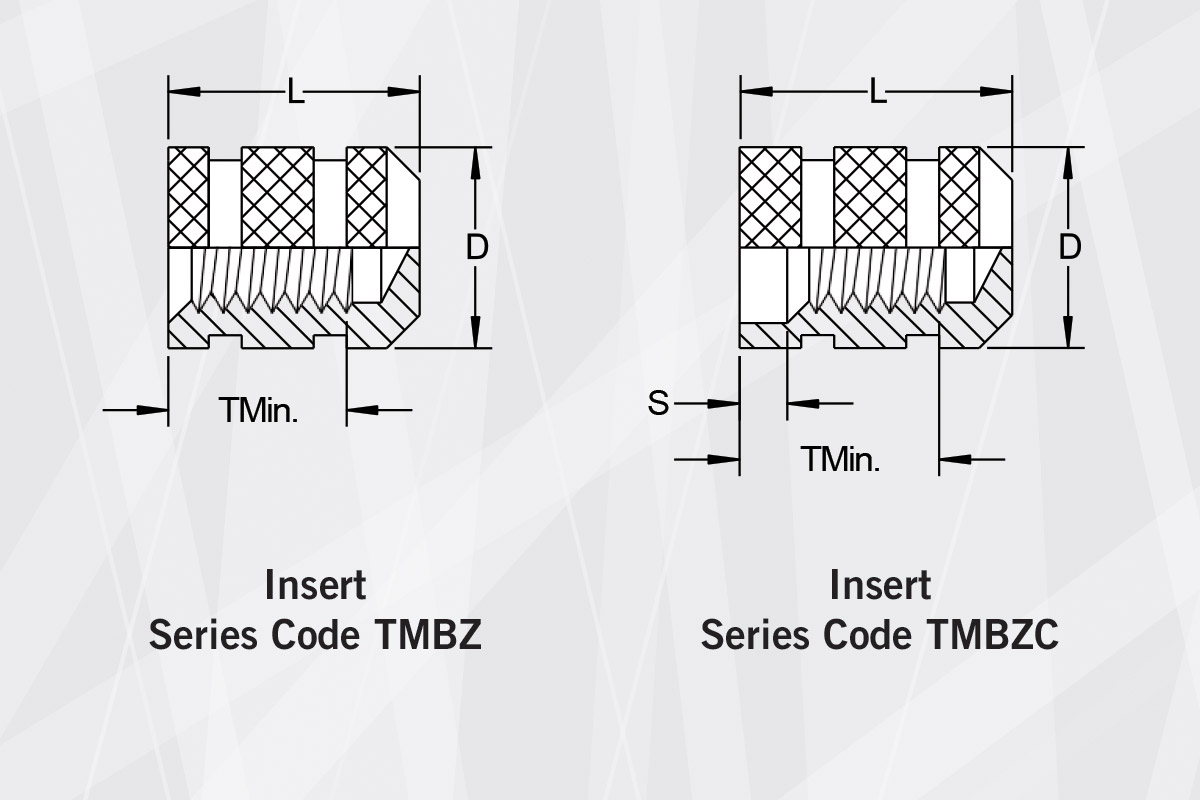

Pin Dimensions

- TMBZ (Click for information)

Insert Thread F G +0.00 -0.25 H ± 0.0125 K N Min. M3 x 0.5 2.50 4.80 2.50 0.75 4.35 M3.5 x 0.6 2.90 5.40 2.90 0.80 5.20 M4 x 0.7 3.30 5.80 3.30 0.85 6.10 M5 x 0.8 4.20 6.70 4.20 0.90 6.80 M6 x 1 5.00 7.50 5.00 0.95 10.2 - TMBZC (Click for information)

Insert Thread F

-0.075

-0.125G

+0.00

-0.25H J K M

±0.0125N

Min.M2 x 0.4 0.85 2.50 1.525-1.550 6.0° 0.20 2.300 3.60 M2.5 x 0.45 0.95 3.00 1.975-2.000 5.0° 0.20 2.800 4.35 M3 x 0.5 1.10 3.50 2.425-2.450 4.5° 0.25 3.125 4.80 M3.5 x 0.6 1.35 4.50 2.825-2.850 4.5° 0.30 3.750 5.20 M4 x 0.7 1.60 5.00 3.225-3.250 4.5° 0.35 4.425 6.10 M5 x 0.8 1.75 5.75 4.125-4.150 5.0° 0.40 5.125 6.80 M6 x 1 1.85 6.75 4.875-4.900 4.5° 0.45 6.600 10.2 M8 x 1.25 2.05 9.00 6.675-6.700 4.5° 0.50 8.500 11.7 M10 x 1.5 2.15 10.00 8.375-8.400 4.5° 0.55 10.500 14.1