General

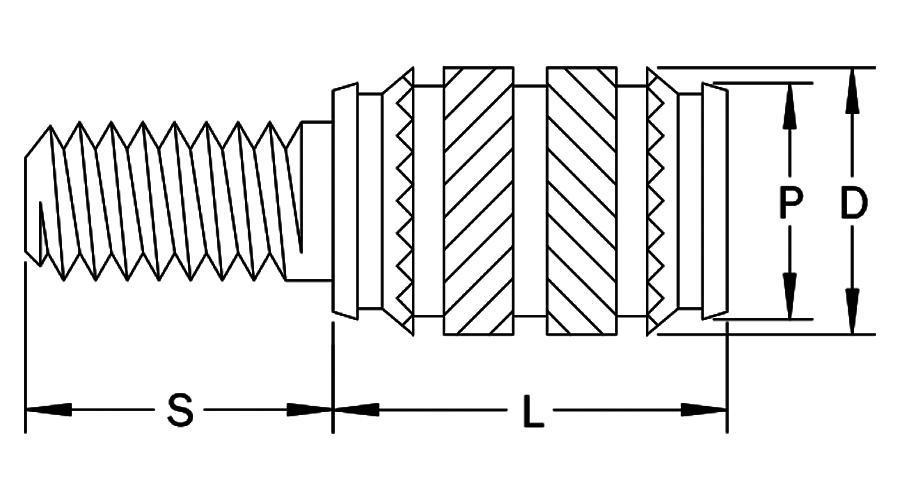

| Insert Thread | Insert Thread Code | Boss | D Insert Diameter | P Pilot Diameter | |

|---|---|---|---|---|---|

| B Hole Dia. +.004 -.000 | W Wall Thickness Min. | ||||

| 2-56 | 256 | .125 | .051 | .137 | .123 |

| 4-40 | 440 | .157 | .063 | .174 | .154 |

| 6-32 | 632 | .189 | .071 | .205 | .185 |

| 8-32 | 832 | .220 | .083 | .239 | .218 |

| 10-24 | 1024 | .252 | .102 | .269 | .249 |

| 10-32 | 1032 | .252 | .102 | .269 | .249 |

| 1/4-20 | 2520 | .315 | .130 | .333 | .312 |

| 1/4-28 | 2528 | .315 | .130 | .333 | .312 |

| 5/16-18 | 3118 | .378 | .177 | .394 | .374 |

| 5/16-24 | 3124 | .378 | .177 | .394 | .374 |

| 3/8-16 | 3716 | .469 | .236 | .485 | .465 |

| 3/8-24 | 3724 | .469 | .236 | .485 | .465 |

| 1/2-13 | 5013 | .630 | .315 | .643 | .622 |

| 1/2-20 | 5020 | .630 | .315 | .643 | .622 |

- All dimensions are in inches and reference unless toleranced.

Insert Length

| Insert Thread | L Insert Length | Insert Length Code |

|---|---|---|

| 2-56 | .118 | 118 |

| .1552 | 155 | |

| 4-40 | .157 | 157 |

| .188 | 188 | |

| .2242 | 224 | |

| 6-32 | .197 | 197 |

| .2792 | 279 | |

| 8-32 | .157 | 157 |

| .188 | 188 | |

| .228 | 288 | |

| .3192 | 319 | |

| 10-24 10-32 | .228 | 228 |

| .3732 | 373 | |

| 1/4-20 1/4-28 | .269 | 269 |

| .374 | 374 | |

| .4982 | 498 | |

| 5/16-18 5/16-24 | .4982 | 498 |

| 3/8-16 3/8-24 | .4982 | 498 |

| 1/2-13 1/2-20 | .6262 | 626 |

- All dimensions are in inches and reference unless toleranced.

- Preferred insert length.

- Custom insert lengths available by request.

Stud Length

| StudThread | Stud Thread Code | D Insert Diameter | S - Stud Length | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| .187 | .250 | .312 | .375 | .437 | .500 | .625 | .750 | .875 | 1.000 | |||

| Stud Length Code | ||||||||||||

| 2-56 | 256 | .137 | 187 | 250 | 312 | - | - | - | - | - | - | - |

| 4-40 | 440 | .174 | 187 | 250 | 312 | 375 | 437 | - | - | - | - | - |

| 6-32 | 632 | .205 | 187 | 250 | 312 | 375 | 437 | 500 | - | - | - | - |

| 8-32 | 832 | .239 | 187 | 250 | 312 | 375 | 437 | 500 | 625 | - | - | - |

| 10-24 | 1024 | .269 | 187 | 250 | 312 | 375 | 437 | 500 | 625 | 750 | - | - |

| 10-32 | 1032 | .269 | 187 | 250 | 312 | 375 | 437 | 500 | 625 | 750 | - | - |

| 1/4-20 | 2520 | .333 | - | 250 | 312 | 375 | 437 | 500 | 625 | 750 | 875 | 1000 |

| 1/4-28 | 2528 | .333 | - | 250 | 312 | 375 | 437 | 500 | 625 | 750 | 875 | 1000 |

| 5/16-18 | 3118 | .394 | - | - | 312 | 375 | 437 | 500 | 625 | 750 | 875 | 1000 |

| 5/16-24 | 3124 | .394 | - | - | 312 | 375 | 437 | 500 | 625 | 750 | 875 | 1000 |

| 3/8-16 | 3716 | .485 | - | - | - | 375 | 437 | 500 | 625 | 750 | 875 | 1000 |

| 3/8-24 | 3724 | .485 | - | - | - | 375 | 437 | 500 | 625 | 750 | 875 | 1000 |

| 1/2-13 | 5013 | .643 | - | - | - | - | - | 500 | 625 | 750 | 875 | 1000 |

| 1/2-20 | 5020 | .643 | - | - | - | - | - | 500 | 625 | 750 | 875 | 1000 |

- All dimensions are in inches and reference unless toleranced.

- Custom stud lengths available by request.