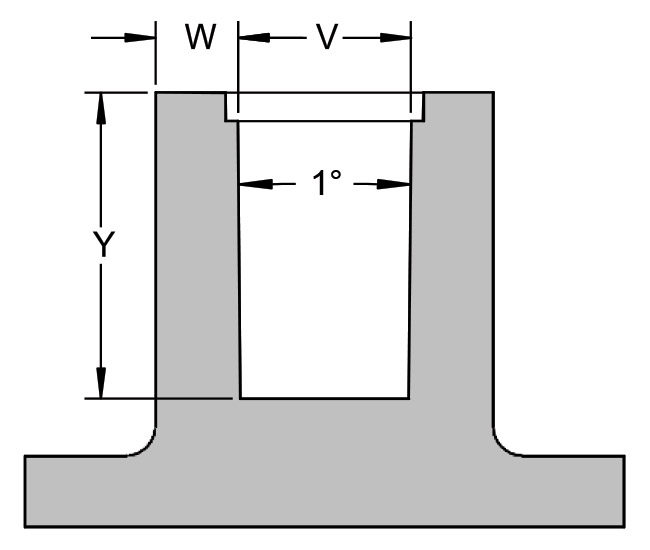

Boss Dimensions

| Insert Thread | L Length | Boss | ||

|---|---|---|---|---|

| V | W | Y | ||

| M1.6 x 0.35 | 2.14 | 2.30-2.50 | 1.00 | 2.20 |

| M2 x 0.4 | 2.14 | 3.00-3.30 | 1.35 | 2.20 |

| M2 x 0.4 | 3.10 | 3.00-3.30 | 1.35 | 3.20 |

| M2 x 0.4 | 4.20 | 3.00-3.30 | 1.35 | 4.30 |

| M2.5 x 0.45 | 4.10 | 3.70-4.00 | 1.70 | 4.20 |

| M2.5 x 0.45 | 5.20 | 3.70-4.00 | 1.70 | 5.30 |

| M3 x 0.5 | 4.10 | 3.70-4.00 | 1.70 | 4.20 |

| M3 x 0.5 | 5.20 | 3.70-4.00 | 1.70 | 5.30 |

| M3.5 x 0.6 | 4.10 | 4.60-5.00 | 2.25 | 4.20 |

| M3.5 x 0.6 | 7.00 | 4.60-5.00 | 2.25 | 7.20 |

| M4 x 0.7 | 5.60 | 5.40-5.90 | 2.50 | 5.80 |

| M4 x 0.7 | 8.50 | 5.40-5.90 | 2.50 | 8.70 |

| M5 x 0.8 | 6.60 | 6.00-6.50 | 2.85 | 6.80 |

| M5 x 0.8 | 10.1 | 6.00-6.50 | 2.85 | 10.3 |

| M6 x 1 | 7.70 | 7.70-8.20 | 3.20 | 7.90 |

| M6 x 1 | 12.3 | 7.70-8.20 | 3.20 | 12.5 |

| M8 x 1.25 | 8.30 | 10.2-10.6 | 4.25 | 8.50 |

| M8 x 1.25 | 10.1 | 10.2-10.6 | 4.25 | 10.3 |

| M8 x 1.25 | 13.8 | 10.2-10.6 | 4.25 | 14.0 |

| M10 x 1.5 | 10.1 | 12.5-13.0 | 5.10 | 10.3 |

| M10 x 1.5 | 10.5 | 12.5-13.0 | 5.10 | 10.7 |

| M10 x 1.5 | 16.1 | 12.5-13.0 | 5.10 | 16.3 |

| M12 x 1.75 | 16.1 | 15.0-15.4 | 5.20 | 16.3 |