General

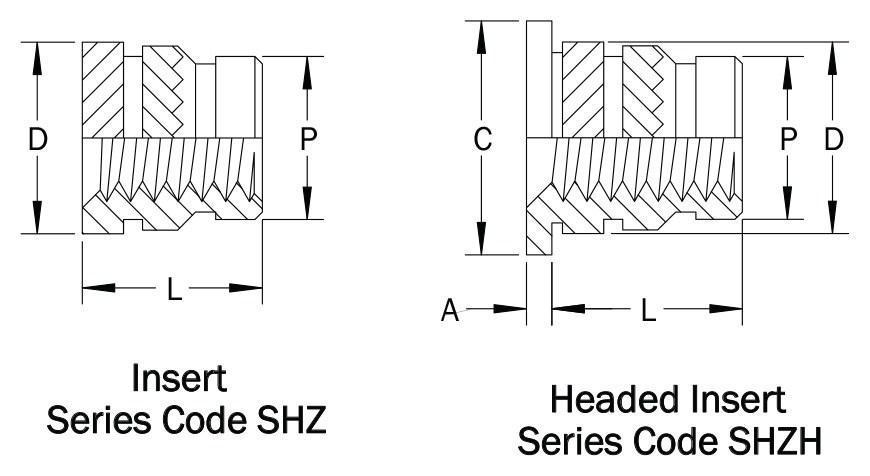

| Insert Thread | Insert Thread Code | Boss | A Head Thickness | C Head Diameter | D Insert Diameter | P Pilot Diameter | |

|---|---|---|---|---|---|---|---|

| B Hole Dia. +.004 -.000 | W Wall Thickness Min. | ||||||

| 0-80 | 080 | .100 | .051 | — | — | .116 | .095 |

| 2-56 | 256 | .126 | .051 | .021 | .187 | .141 | .123 |

| 4-40 | 440 | .157 | .063 | .024 | .218 | .181 | .154 |

| 6-32 | 632 | .189 | .071 | .030 | .250 | .214 | .185 |

| 8-32 | 832 | .220 | .083 | .036 | .281 | .248 | .218 |

| 10-24 | 1024 | .252 | .102 | .043 | .312 | .278 | .249 |

| 10-32 | 1032 | .252 | .102 | .043 | .312 | .278 | .249 |

| 1/4-20 | 2520 | .315 | .130 | .053 | .375 | .341 | .312 |

| 1/4-28 | 2528 | .315 | .130 | .053 | .375 | .341 | .312 |

| 5/16-18 | 3118 | .378 | .177 | .053 | .437 | .403 | .374 |

| 5/16-24 | 3124 | .378 | .177 | .053 | .437 | .403 | .374 |

| 3/8-16 | 3716 | .469 | .236 | .063 | .551 | .494 | .465 |

| 3/8-24 | 3724 | .469 | .236 | .063 | .551 | .494 | .465 |

| 1/8-NPT | 125NPT | .453 | .236 | — | — | .479 | .450 |

| 1/2-13 | 5013 | .630 | .315 | .079 | .748 | .657 | .622 |

| 1/2-20 | 5020 | .630 | .315 | .079 | .748 | .657 | .622 |

Insert Length

| Insert Thread | L Insert Length | Insert Length Code |

|---|---|---|

| 0-80 | .1252 | 125 |

| 2-56 | .100 | 100 |

| .115 | 115 | |

| .125 | 125 | |

| .138 | 138 | |

| .1572 | 157 | |

| 4-40 | .096 | 096 |

| .140 | 140 | |

| .170 | 170 | |

| .2262 | 226 | |

| .250 | 250 | |

| .321 | 321 | |

| 6-32 | .125 | 125 |

| .150 | 150 | |

| .205 | 205 | |

| .226 | 226 | |

| .250 | 250 | |

| .2812 | 281 | |

| .375 | 375 | |

| 8-32 | .115 | 115 |

| .150 | 150 | |

| .185 | 185 | |

| .250 | 250 | |

| .281 | 281 | |

| .3212 | 321 | |

| 10-24 10-32 | .185 | 185 |

| .226 | 226 | |

| .250 | 250 | |

| .310 | 310 | |

| .3752 | 375 | |

| .400 | 400 | |

| 1/4-20 1/4-28 | .250 | 250 |

| .312 | 312 | |

| .348 | 348 | |

| .5002 | 500 | |

| 5/16-18 5/16-24 | .5002 | 500 |

| 3/8-16 3/8-24 | .5002 | 500 |

| 1/8 NPT | .6252 | 625 |

| 1/2-13 1/2-20 | .6252 | 625 |