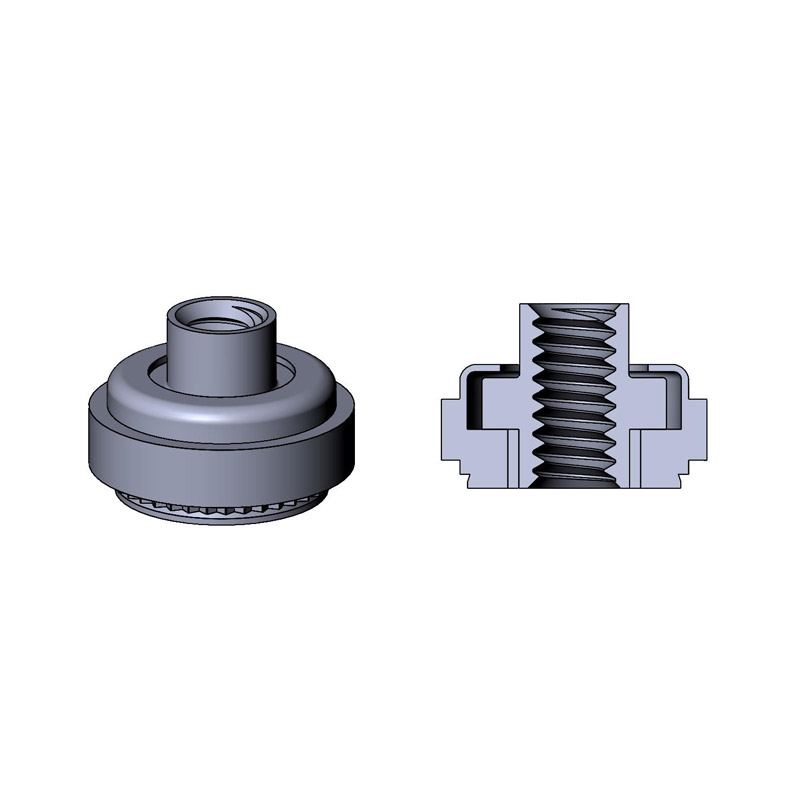

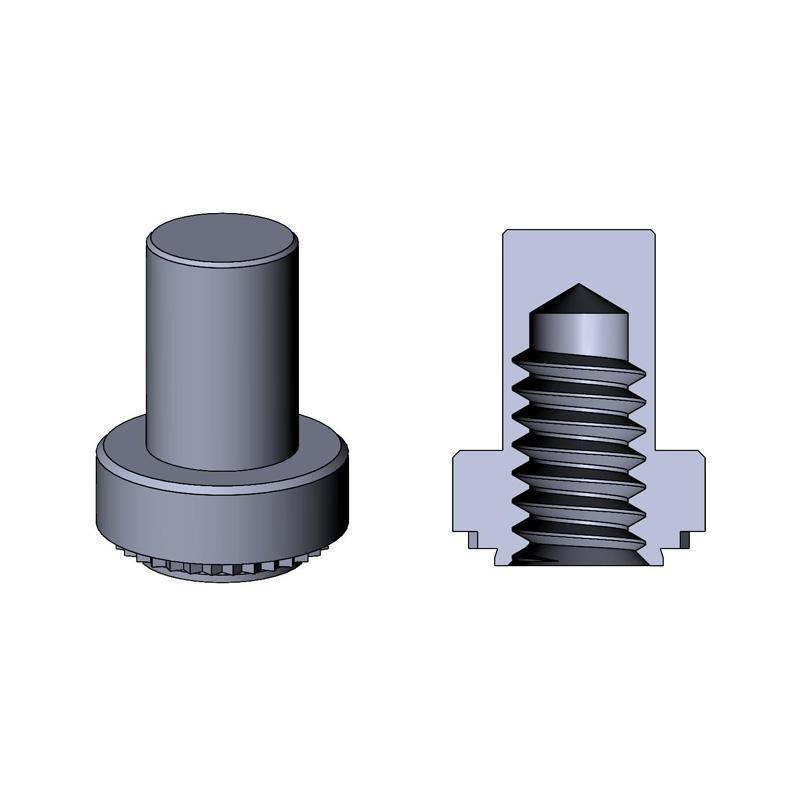

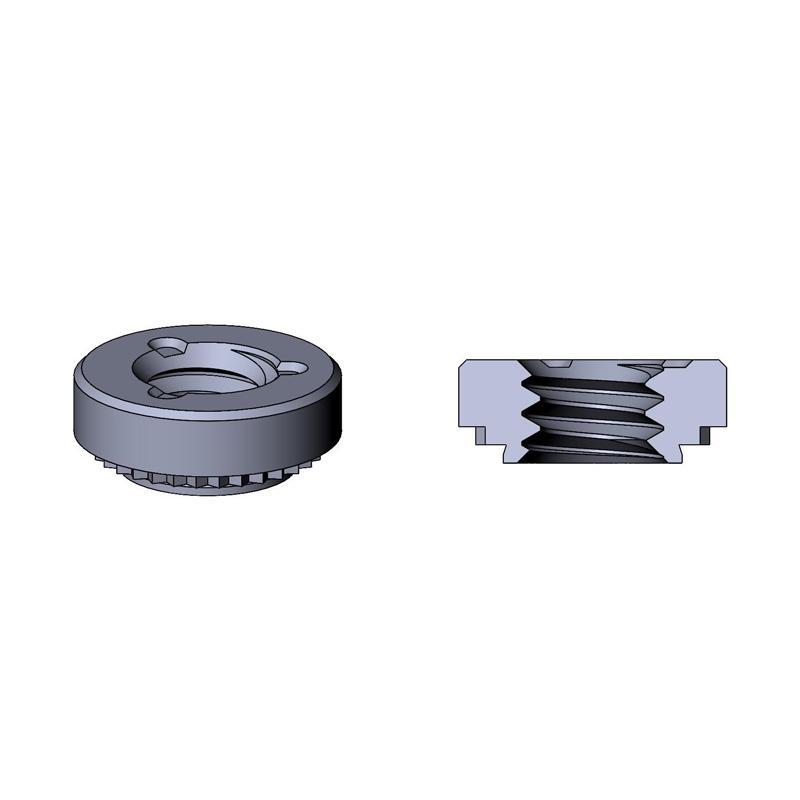

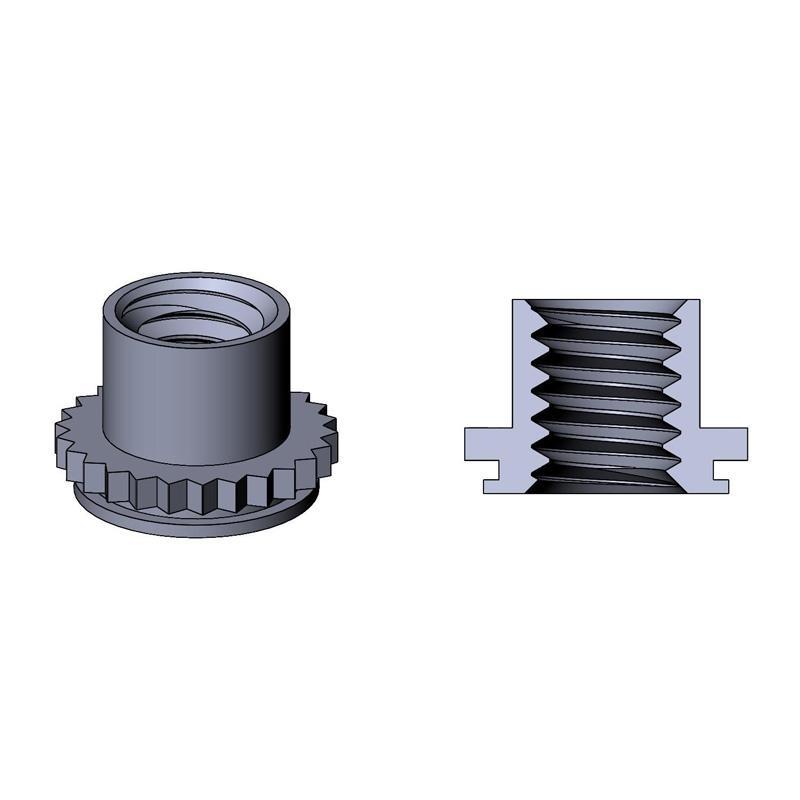

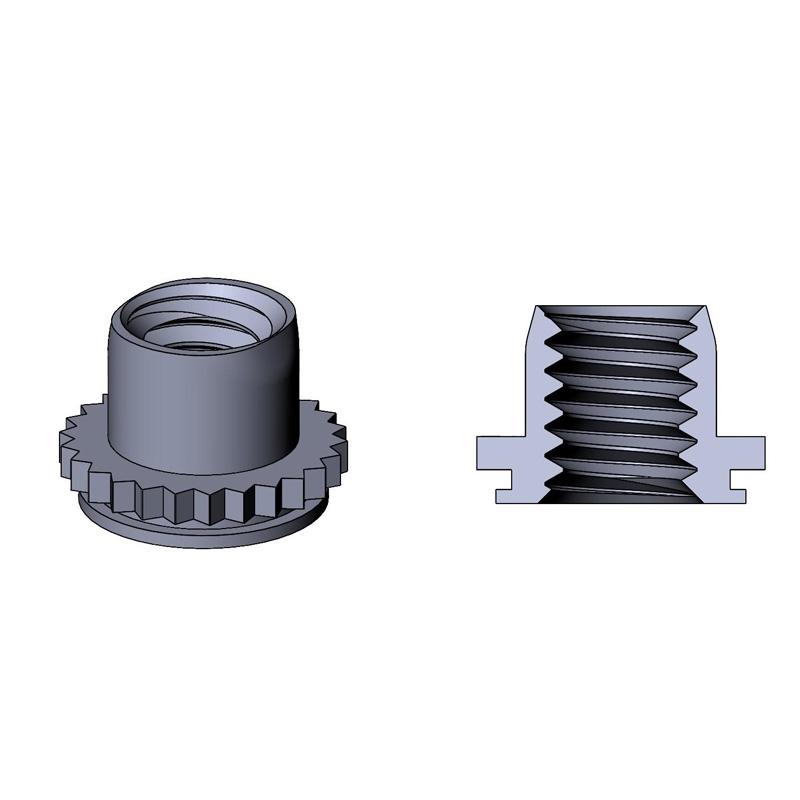

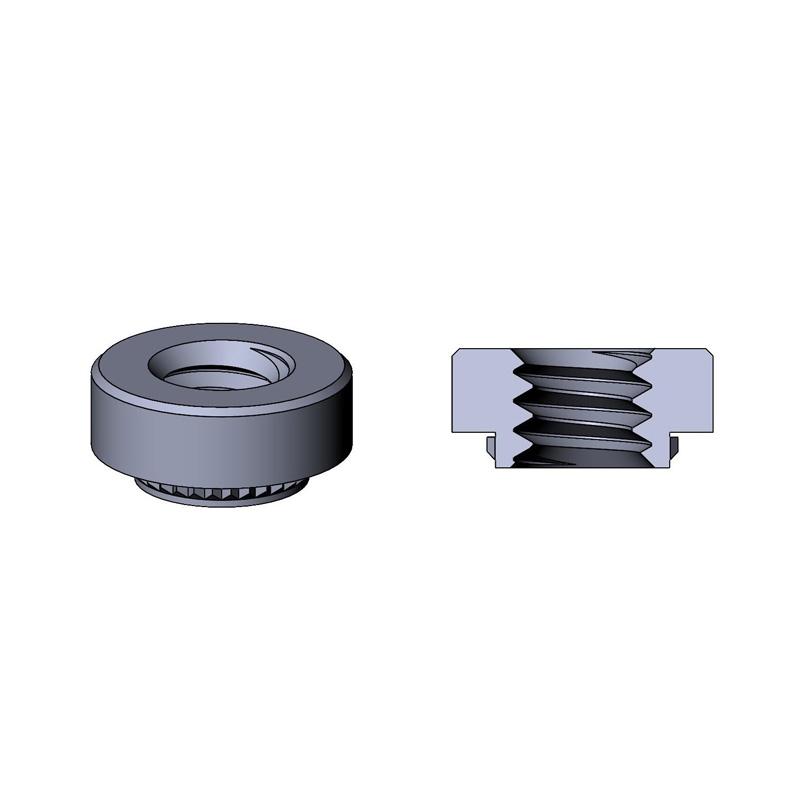

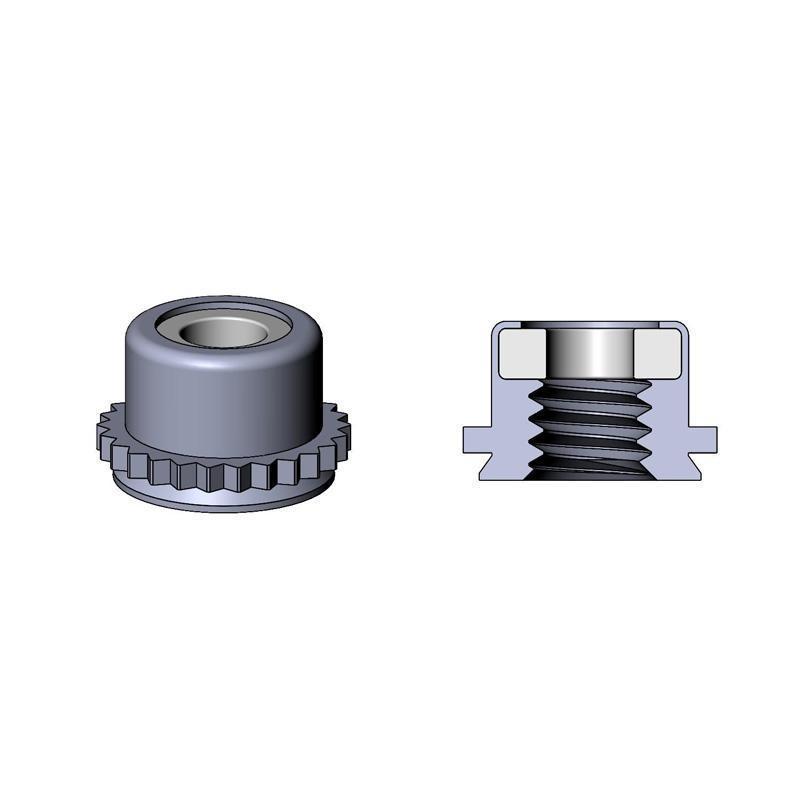

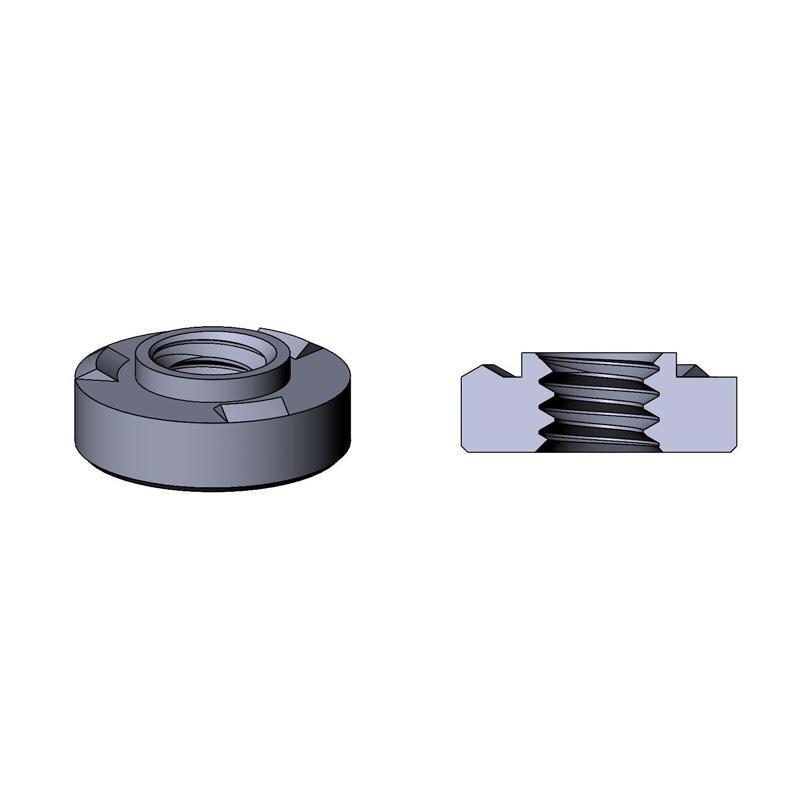

Self-clinching Nuts

Enhance Assembly Efficiency with PENCOM’s Self-Clinching Fasteners for Thin Sheet Metals and Circuit Boards

Self-Clinching nuts provide permanent threads in sheet metal and printed circuit boards. These products install by pressing in to softer metals and displacing the material around it, locking it in place. PENCOM provides Stainless Steel and Carbon Steel nuts for a variety of applications and installation methods, and are available in multiple variations; such as locking, self-clinching, miniature, broaching, and thin panel applications. These products are either machined or cold-formed to prevent defects during installation and ensure performance. Contact us for more information.