General

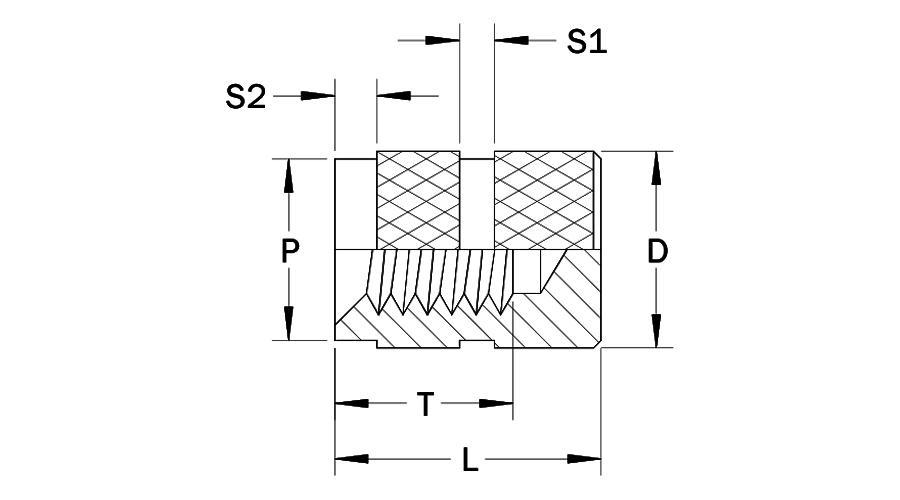

| Insert Thread | Insert Thread Code | D Stock Dia. Before Knurl | P End Diameter ±0.13 | S1 | S2 | Thread Minor Diameter |

| M2 x 0.4 | M2 | 3.96 | 3.61 | 0.80 | 0.80 | 1.58 -1.67 |

| M2.5 x 0.45 | M2.5 | 4.78 | 4.34 | 0.80 | 0.80 | 2.03 -2.14 |

| M3 x 0.5 | M3 | 4.78 | 4.34 | 0.80 | 0.80 | 2.47- 2.59 |

| M3.5 x 0.6 | M3.5 | 5.56 | 5.13 | 0.80 | 1.60 | 2.87- 3.01 |

| M4 x 0.7 | M4 | 6.35 | 5.74 | 1.20 | 1.60 | 3.25 – 3.42 |

| M5 x 0.8 | M5 | 7.14 | 6.57 | 1.20 | 1.60 | 4.15 – 4.34 |

| M6 x 1.0 | M6 | 8.74 | 8.15 | 1.60 | 2.40 | 4.94 – 5.16 |

| M8 x 1.25 | M8 | 11.13 | 10.26 | 1.98 | 2.40 | 6.78 – 6.92 |

Insert Length

| Insert Thread | L Insert Length ±0.13 | Insert Length Code | T Thread Depth Min. |

| M2 x 0.4 | 3.96 | 3.96 | 1.60 |

| 5.56 | 5.56 | 2.40 | |

| 6.35 | 6.35 | 3.20 | |

| 7.37 | 7.37 | 4.00 | |

| 8.38 | 8.38 | 4.80 | |

| M2.5 x 0.45 | 4.78 | 4.78 | 2.77 |

| 6.35 | 6.35 | 3.68 | |

| 7.14 | 7.14 | 4.57 | |

| 9.53 | 9.53 | 5.46 | |

| 10.31 | 10.31 | 6.35 | |

| M3 x 0.5 | 4.78 | 4.78 | 2.00 |

| 5.21 | 5.21 | 3.00 | |

| 7.13 | 7.13 | 4.30 | |

| 8.73 | 8.73 | 5.80 | |

| 10.31 | 10.31 | 7.10 | |

| 11.13 | 11.13 | 8.30 | |

| 11.89 | 11.89 | 9.06 | |

| M3.5 x 0.6 | 5.56 | 5.56 | 2.40 |

| 6.35 | 6.35 | 3.73 | |

| 8.73 | 8.73 | 5.60 | |

| 10.31 | 10.31 | 7.20 | |

| 11.91 | 11.91 | 8.80 | |

| 12.29 | 12.29 | 9.18 | |

| 13.48 | 13.48 | 10.00 | |

| M4 x 0.7 | 6.35 | 6.35 | 3.30 |

| 8.73 | 8.73 | 5.60 | |

| 10.31 | 10.31 | 7.20 | |

| 11.91 | 11.91 | 8.80 | |

| 12.29 | 12.29 | 9.18 | |

| 13.48 | 13.48 | 10.00 | |

| M5 x 0.8 | 7.13 | 7.13 | 3.90 |

| 11.12 | 11.12 | 6.10 | |

| 11.91 | 11.91 | 8.80 | |

| 13.48 | 13.48 | 10.30 | |

| M6 x 1.0 | 8.73 | 8.73 | 4.83 |

| 9.53 | 9.53 | 5.63 | |

| 13.49 | 13.49 | 7.62 | |

| 15.87 | 15.87 | 9.53 | |

| 17.48 | 17.48 | 10.00 | |

| 18.26 | 18.26 | 11.57 | |

| 19.05 | 19.05 | 12.00 | |

| 20.80 | 20.80 | 13.59 | |

| M8 x 1.25 | 11.13 | 11.13 | 5.72 |

| 11.91 | 11.91 | 6.49 | |

| 15.09 | 15.09 | 8.64 | |

| 18.24 | 18.24 | 11.55 | |

| 20.62 | 20.62 | 14.09 | |

| 22.23 | 22.23 | 15.74 |

| Insert Thread Code | Insert Length Code | Host Material | Pull-out (kN) | Torque-out (N-m) |

| M2 | 5.56 | ABS | 0.62-0.66 | 0.62-0.66 |

| Polycarbonate | 0.70-0.73 | 0.66-0.70 | ||

| 8.38 | ABS | 0.64-0.67 | 0.64-0.68 | |

| Polycarbonate | 0.71-0.74 | 0.67-0.72 | ||

| M2.5 | 6.35 | ABS | 1.0 6 -1.11 | 0.64 – 0.70 |

| Polycarbonate | 1.12-1.17 | 0.73-0.77 | ||

| 9.53 | ABS | 1.08-1.12 | 0.66-0.72 | |

| Polycarbonate | 1.16-1.19 | 0.74-0.79 | ||

| M3 | 7.13 | ABS | 1.06-1.11 | 0.64-0.70 |

| Polycarbonate | 1.12-1.17 | 0.73-0.77 | ||

| 10.31 | ABS | 1.08-1.12 | 0.66-0.72 | |

| Polycarbonate | 1.16-1.19 | 0.74-0.79 | ||

| M4 | 8.73 | ABS | 2.31-2.35 | 1.59-1.69 |

| Polycarbonate | 2.38-2.42 | 1.74-1.81 | ||

| 11.91 | ABS | 2.33-2.37 | 1.69-1.78 | |

| Polycarbonate | 2.40-2.43 | 1.79-1.85 | ||

| M5 | 11.12 | ABS | 2.77-2.82 | 5.87-6.44 |

| Polycarbonate | 2.84-2.88 | 6.32-6.66 | ||

| 11.91 | ABS | 2.79-2.83 | 6.10-6.55 | |

| Polycarbonate | 2.87-2.89 | 6.44-6.78 | ||

| M6 | 13.49 | ABS | 3.98-4.04 | 11.6-12.2 |

| Polycarbonate | 4.05-4.12 | 12.0-12.5 |