General

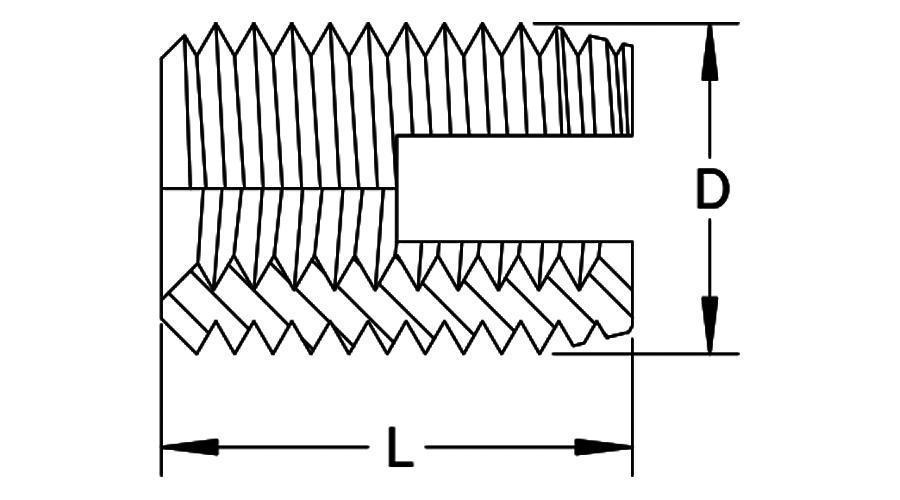

| Insert Thread | Insert Thread Code | L Insert Length | Insert Length Code | Boss Hole Dia. B | A Head Thickness | C Head Diameter | D Insert Diameter Max. | |

| Thermo– plastics +.004 -.000 | Thermo– setting +.004 -.000 | |||||||

| 2-56 | 256 | .236 | 236 | .157-.161 | .161-.169 | .023 | .236 | .177 |

| 4-40 | 440 | .236 | 236 | .157-.161 | .161-.169 | .023 | .236 | .177 |

| 6-32 | 632 | .315 | 315 | .209-.213 | .217-.224 | .029 | .295 | .236 |

| 8-32 | 832 | .315 | 315 | .228-.232 | .236-.244 | .035 | .312 | .256 |

| 10-24 | 1024 | .394 | 394 | .280-.283 | .287-.299 | .042 | .374 | .315 |

| 10-32 | 1032 | .394 | 394 | .280-.283 | .287-.299 | .042 | .374 | .315 |

| 1/4-20 | 2520 | .551 | 551 | .339-.346 | .354-.370 | .052 | .472 | .394 |

| 1/4-28 | 2528 | .551 | 551 | .339-.346 | .354-.370 | .052 | .472 | .394 |

| 5/16-18 | 3118 | .591 | 591 | .417-.425 | .433-.449 | .052 | .551 | .472 |

| 5/16-24 | 3124 | .591 | 591 | .417-.425 | .433-.449 | .052 | .551 | .472 |

| 3/8-16 | 3716 | .709 | 709 | .496-.504 | .512-.528 | .062 | .630 | .551 |

| 3/8-24 | 3724 | .709 | 709 | .496-.504 | .512-.528 | .062 | .630 | .551 |

| 1/2-13 | 5013 | .866 | 866 | .575-.583 | .591-.606 | .062 | .709 | .630 |

| 1/2-20 | 5020 | .866 | 866 | .575-.583 | .591-.606 | .062 | .709 | .630 |