General

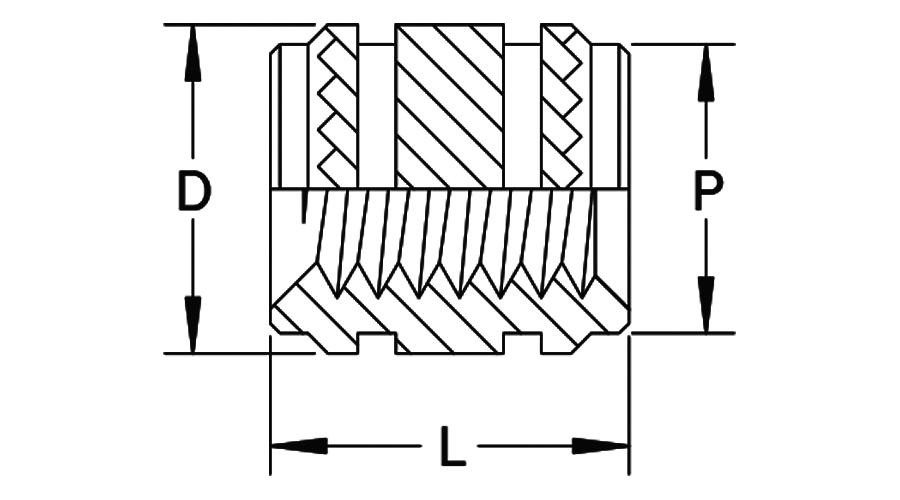

| Insert Thread | Insert Thread Code | Boss | A Head Thickness | C Head Diameter | D Insert Diameter | P Pilot Diameter | |

|---|---|---|---|---|---|---|---|

| B Hole Dia. +0.10 -0.00 | W Wall Thickness Min. | ||||||

| M1 x 0.25 | M1 | 1.75 | 0.70 | — | — | 2.10 | 1.70 |

| M1.2 x 0.25 | M1.2 | 1.75 | 0.70 | — | — | 2.10 | 1.70 |

| M1.4 x 0.3 | M1.4 | 2.15 | 0.80 | 0.40 | 3.00 | 2.50 | 2.10 |

| M1.6 x 0.35 | M1.6 | 2.15 | 0.80 | 0.40 | 3.00 | 2.50 | 2.10 |

| M2.0 x 0.4 | M2.0 | 2.65 | 0.80 | 0.40 | 3.50 | 3.00 | 2.60 |

| M2.5 x 0.45 | M2.5 | 3.20 | 1.00 | 0.40 | 4.00 | 3.65 | 3.15 |

Insert Length

| Insert Thread | L Insert Length | Insert Length Code |

|---|---|---|

| M1 | 2.50 | 2.50 |

| M1.2 | 2.50 | 2.50 |

| M1.4 | 3.00 | 3.00 |

| M1.6 | 2.00 | 2.00 |

| 2.20 | 2.20 | |

| 2.50 | 2.50 | |

| 3.00 | 3.00 | |

| M2.0 | 3.00 | 3.00 |

| M2.5 | 4.00 | 4.00 |