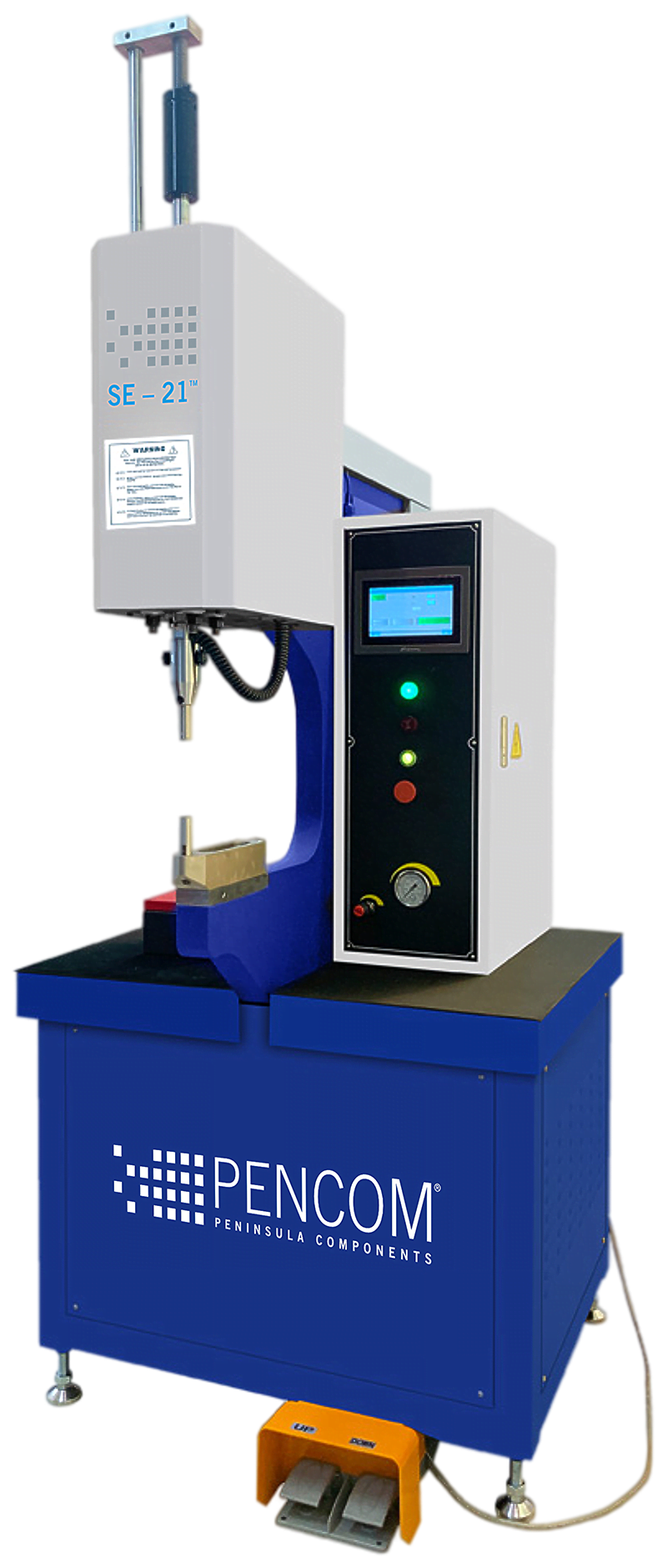

SE – 21™

Fastener Insertion Technologies™

Specifications:

- Force Range: 2-57KN (450 to 12,814lbs)

- Throat Depth: 450mm (18 inch)

- Throat Height: 400mm (16 inch)

- Stroke Length: 200mm (8 inch)

- Insertion Max Capability: Carbon steel Nut M10, Stud M8/Standoff M6,2-56″ to 3/8-16″

- Motor Power: 2.25KW

- Pump: Single pump

- Cylinder speed: 70-100mm/s

- Tool change method: Manual

- Force setting: Manual setting

- TIS (Turret Insertion System): Manual adjust force TIS, Manual TIS (Optional) No PLC

- Oil tank capacity: 60L (15.8 gallons)

- Standard supply voltage: 380V/3Phase/50-60Hz or customized (Optional)

- Current: 6A

- Repeatability: ±1% of force setting

- Hydraulic oil: Mobil DTE 10 Excel 46

- Air pressure: 0.4-0.6MPa (max 87 psi)

- Dimension (L x W x H): 930 x 1100 x 2000mm, 36.6″ x 43.3″ x 78.7″

- Weight: 650Kg (1,433 lbs)

Standard Features:

- Auto Stop: This feature reduces risk and harm to operators. As the press is in motion, it will stop when encountering a foreign object.

- Positive Stop: This type of adjustable control energizes a solenoid valve to extend or retract the cylinder at the appropriate time. When the extend valve is energized, the cylinder begins to extend and it moves until it hits a stop at the end of its travel. When the solenoid for retraction is energized, the shaft will begin to retract until it hits the stop at the end of its travel. This is an advantage in softer materials such as PCB, plastic, and aluminum.

- Batch Counter: The batch counter will automatically count the number of installed fasteners in a single application, and features a buzzer to indicate when the total installations are complete.

Optional Features:

- Laser Locating: This system allows the operator to see where each fastener will be installed with precision.

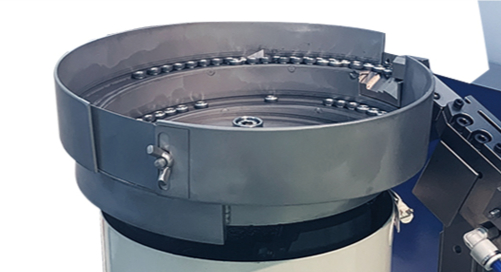

- Modular Auto-Feed System (MAS): MAS handles nuts, studs, and stoffs ranging from M2 to M6 (2-56 to 1/4-20) and a maximum length of 25mm (1 inch). This system features a high-quality vibration bowl for the movement of parts, and a variable frequency vibration controller.

- Automatic Tooling System: Compatible with the Modular Auto-Feed System, this feature includes shuttle tooling attachments for nuts, studs, and standoffs, as well as an attachment for automatic bottom feed tooling.