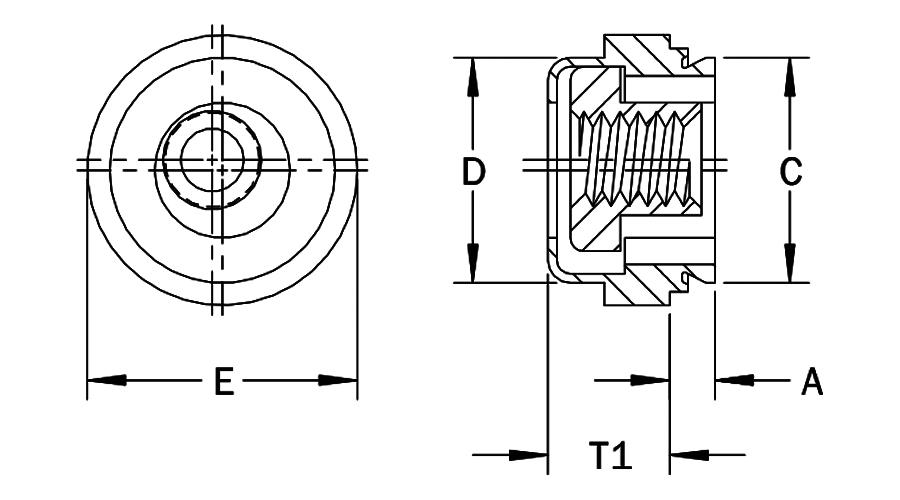

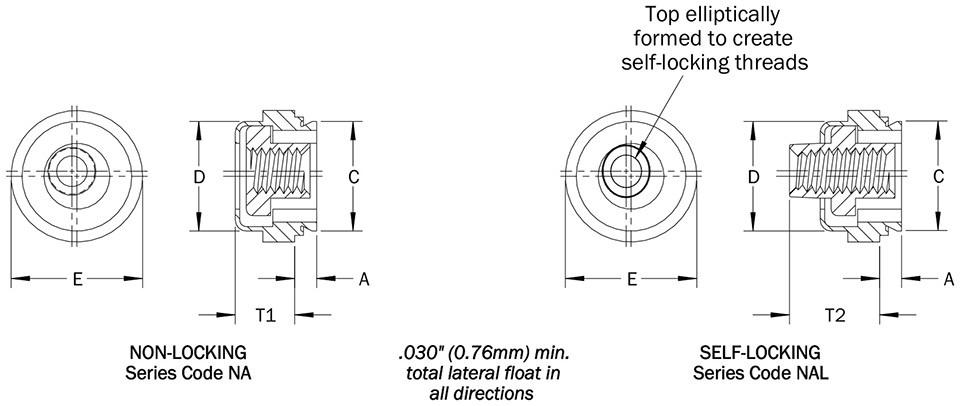

NA Floating Inch Self-clinching Nuts

Self-Clinching Nuts Features

- Internal floating self-clinching nuts feature allows up to .030” (0.76mm) lateral adjustment to compensate for misalignment with mating fastener.

- Permanent installation in aluminum, carbon steel and stainless steel sheets.

- Self-locking version provides uniformity of locking torque equivalent to NASM25027 specifications. See the Pencom website technical reference Locking Fastener Conformance to NASM25027 for complete information.

- Choice of RoHS–compliant materials and finishes.