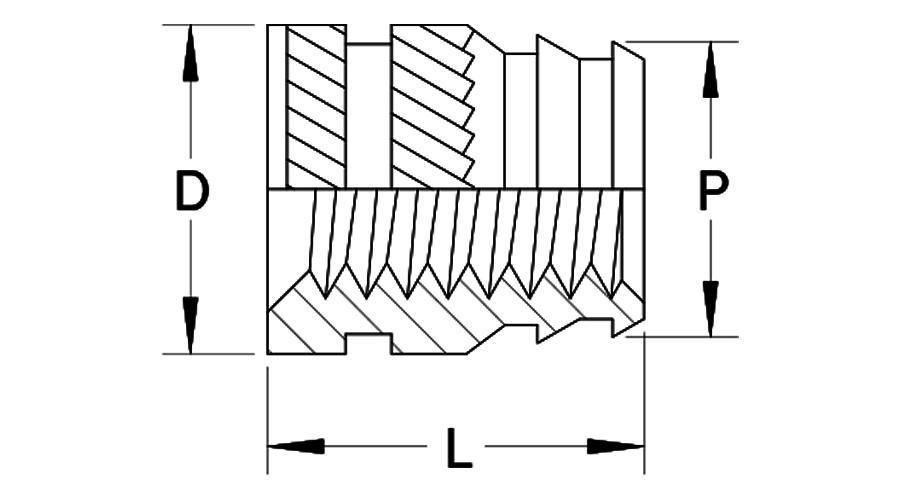

THZ Tapered Hole Inserts Metric Inserts for Plastic

Features

- Designed to be used in an 8° tapered hole.

- Rapid self–aligning installation using heat or ultrasonic.

- Combination of knurls and vanes provide high pull–out and torque–out resistance.

- Circular flange creates an attractive installation by preventing escape of plastic.

- Available in a wide variety of thread sizes and lengths.