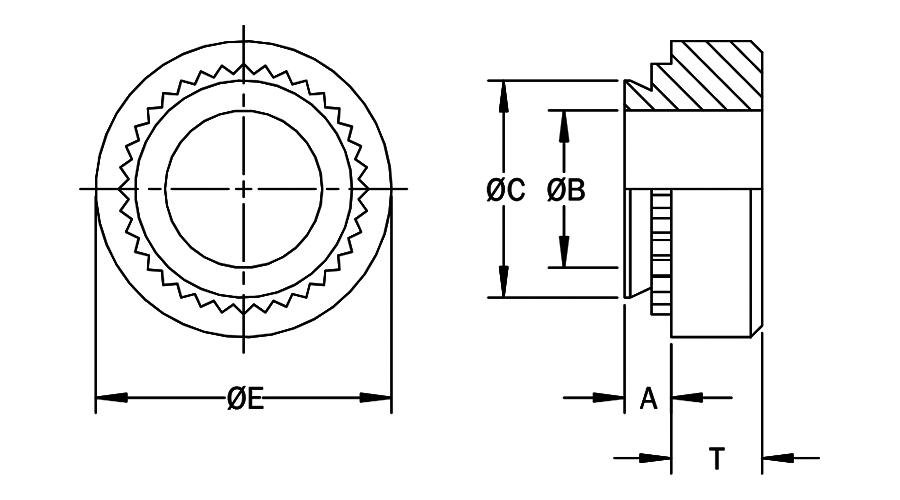

GRA Self-Clinching Guide Pin Receptacle Nuts Metric Guide Pins

Features

- Precise fit with Pencom’s GA, GB, GF, GN & GP guide pins.

- Helps maintain parallelism between mating surfaces during assembly.

- Permanent installation in aluminum, carbon steel, stainless steel and fiberglass (pcb) sheets.

- Choice of RoHS compliant materials and finishes.