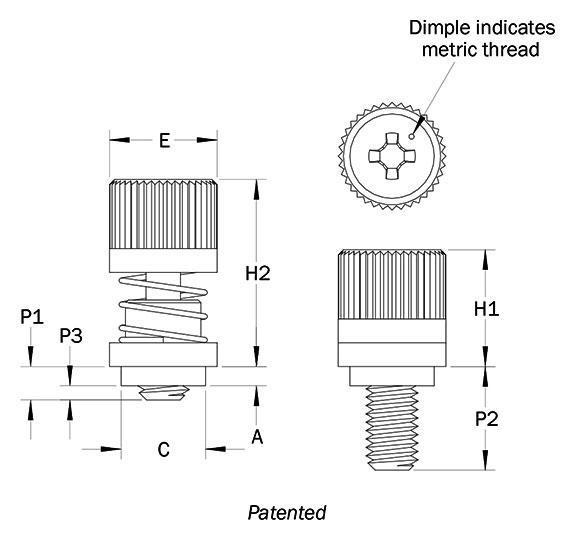

CNC Narrow Flare-In Metric Captive Screws

- Narrow design for limited space applications.

- New contemporary appearance.

- Require low installation forces and are popular choices for painted sheets and close-to-edge applications.

- Choice of RoHS-compliant materials and finishes.