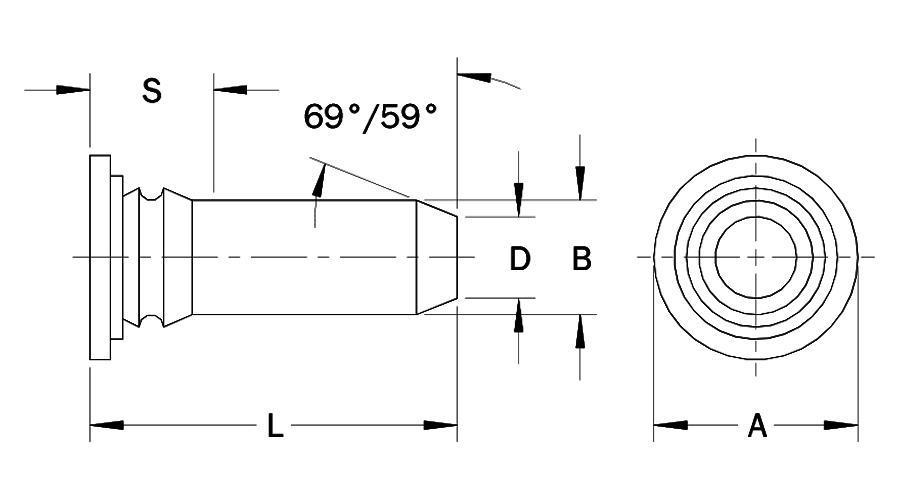

GT Self-clinching Pilot Pins

Inch Guide Pins

Features

- Satisfy a wide variety of alignment, location and pivot applications.

- Self-clinching design installs easily and permanently with a flush appearance on the back of thin panels and sheets.

- Available in a variety of RoHS-compliant materials and finishes.