General

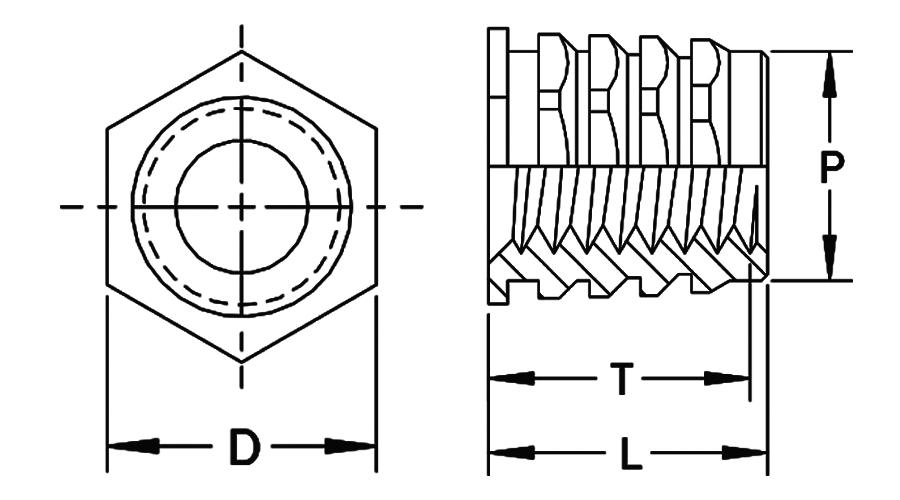

| Insert Thread | Insert Thread Code | L Insert Length Max. | Insert Length Code | Boss | D Width Across Flats | P Pilot Diameter Max. | T Full Thread Depth Min. (2) | |

| B Hole Dia. +.003 -.000 | W Wall Thickness Min. | |||||||

| 2-56 | 256 | .230 | 230 | .187 | .157 | .187 | .186 | .212 |

| 4-40 | 440 | .230 | 230 | .187 | .157 | .187 | .186 | .212 |

| 6-32 | 632 | .230 | 230 | .187 | .157 | .187 | .186 | .212 |

| 8-32 | 832 | .265 | 265 | .250 | .188 | .250 | .249 | .248 |

| 10-24 | 1024 | .265 | 265 | .250 | .188 | .250 | .249 | .248 |

| 10-32 | 1032 | .265 | 265 | .250 | .188 | .250 | .249 | .248 |

| 1/4-20 | 2520 | .315 | 315 | .312 | .219 | .312 | .311 | .300 |

| 1/4-28 | 2528 | .315 | 315 | .312 | .219 | .312 | .311 | .300 |

| 5/16-18 | 3118 | .365 | 365 | .375 | .288 | .375 | .374 | .345 |

| 5/16-24 | 3124 | .365 | 365 | .375 | .288 | .375 | .374 | .345 |

| Insert Thread Code | Boss Material | Installation (lbs) | Pull–out (lbs) | Torque–out (in-lbs) |

| 440 | ABS | 225 | 125 | 4 |

| Polycarbonate | 600 | 280 | 16 | |

| 632 | ABS | 225 | 125 | 4 |

| Polycarbonate | 600 | 280 | 16 | |

| 832 | ABS | 300 | 135 | 10 |

| Polycarbonate | 600 | 380 | 42 | |

| 1024 1032 | ABS | 300 | 135 | 10 |

| Polycarbonate | 600 | 380 | 42 | |

| 2520 2528 | ABS | 400 | 235 | 28 |

| Polycarbonate | — | — | — |