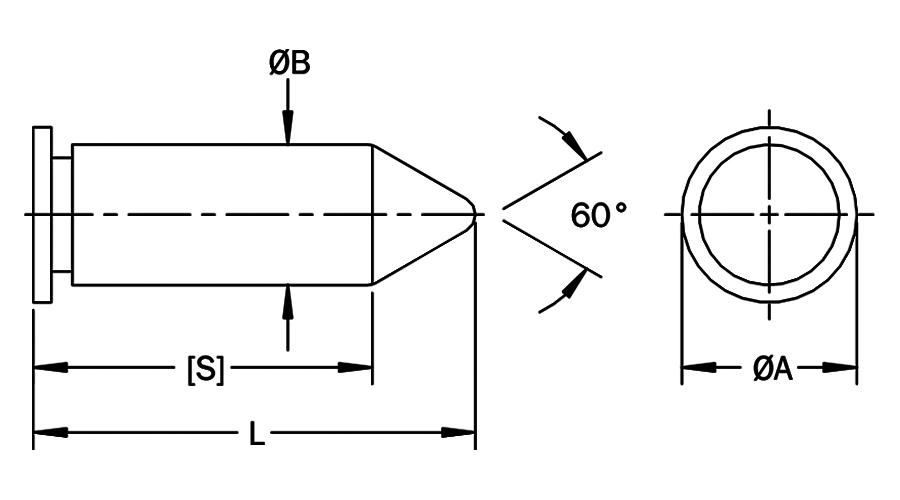

GP Self-Clinching Guide Pins

Metric Guide Pins

Features

- Precisely locates stacked and/or matingpanels and chasses.

- Self– clinching design provides permanentinstallation in panels 1.02mm thick.

- Wide range of pin diameters and lengths accommodates most alignment requirements. Custom sizes available by request.

- Choice of RoHS compliant materials and finishes.