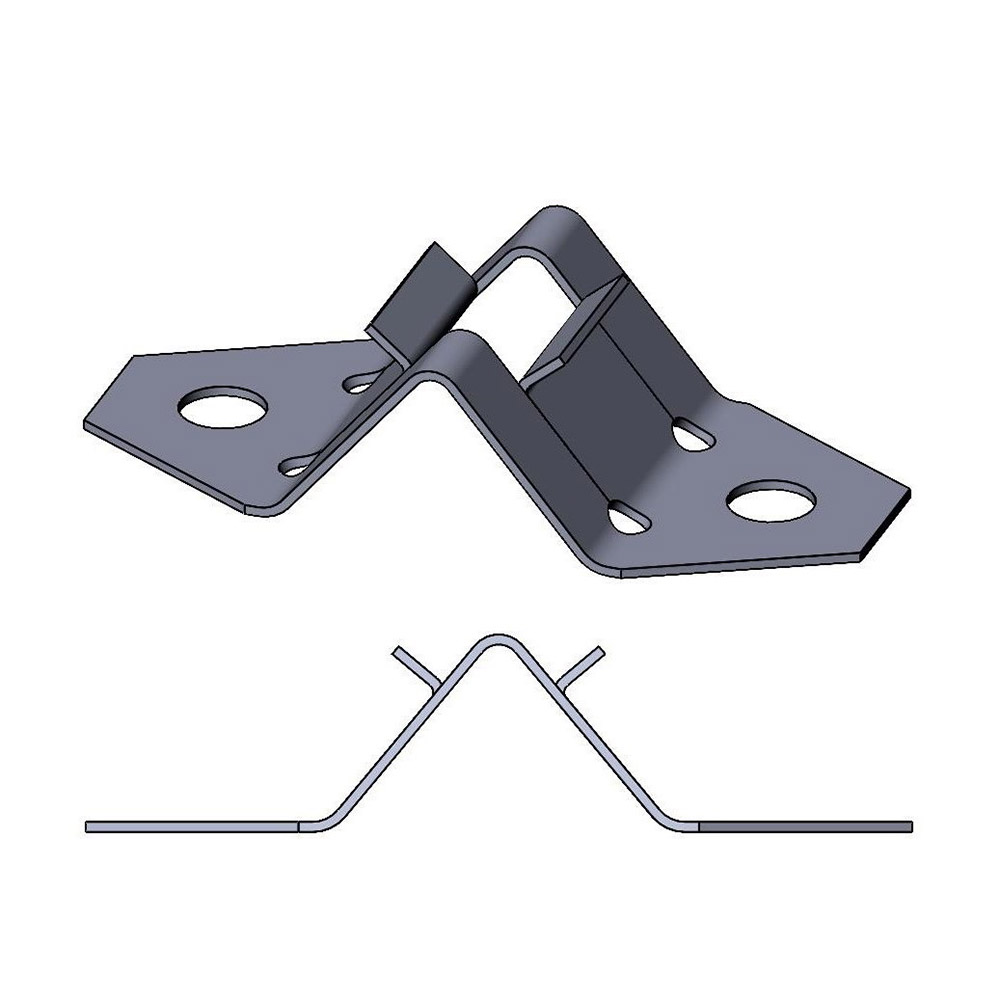

Ball Studs and Clips

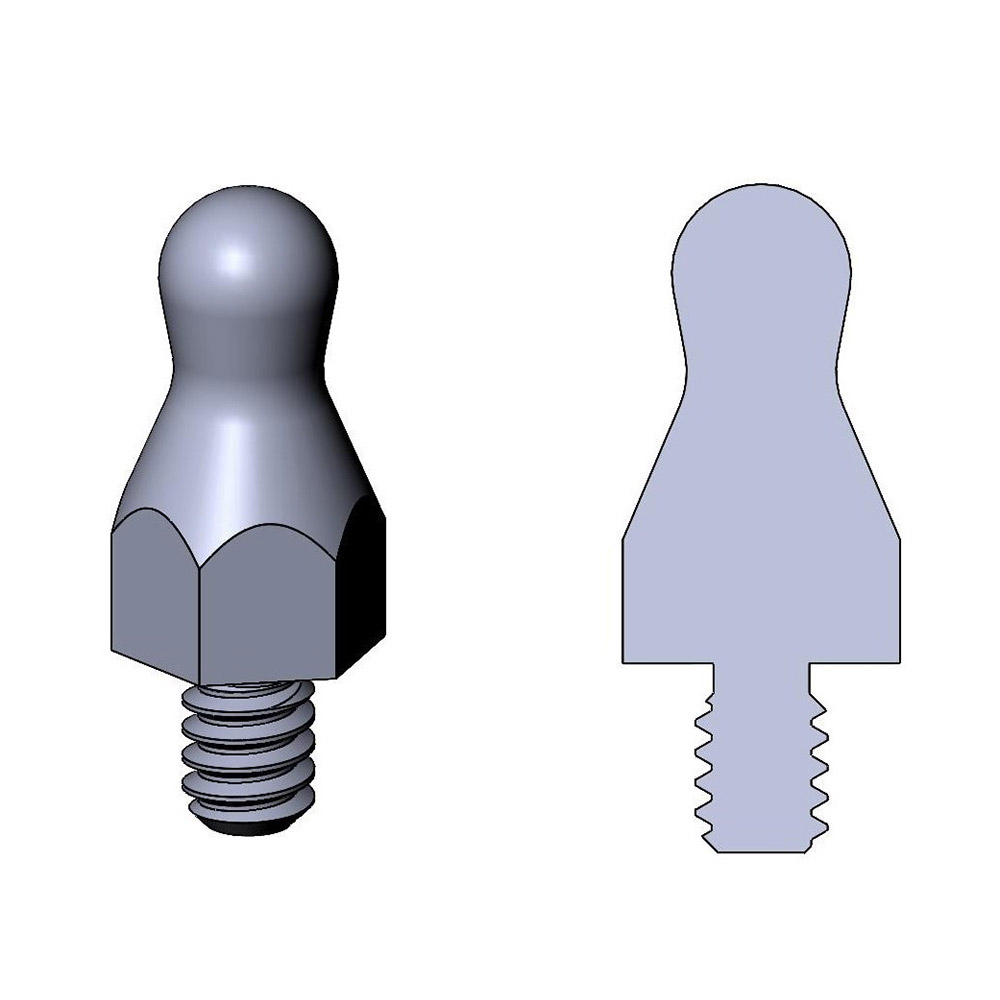

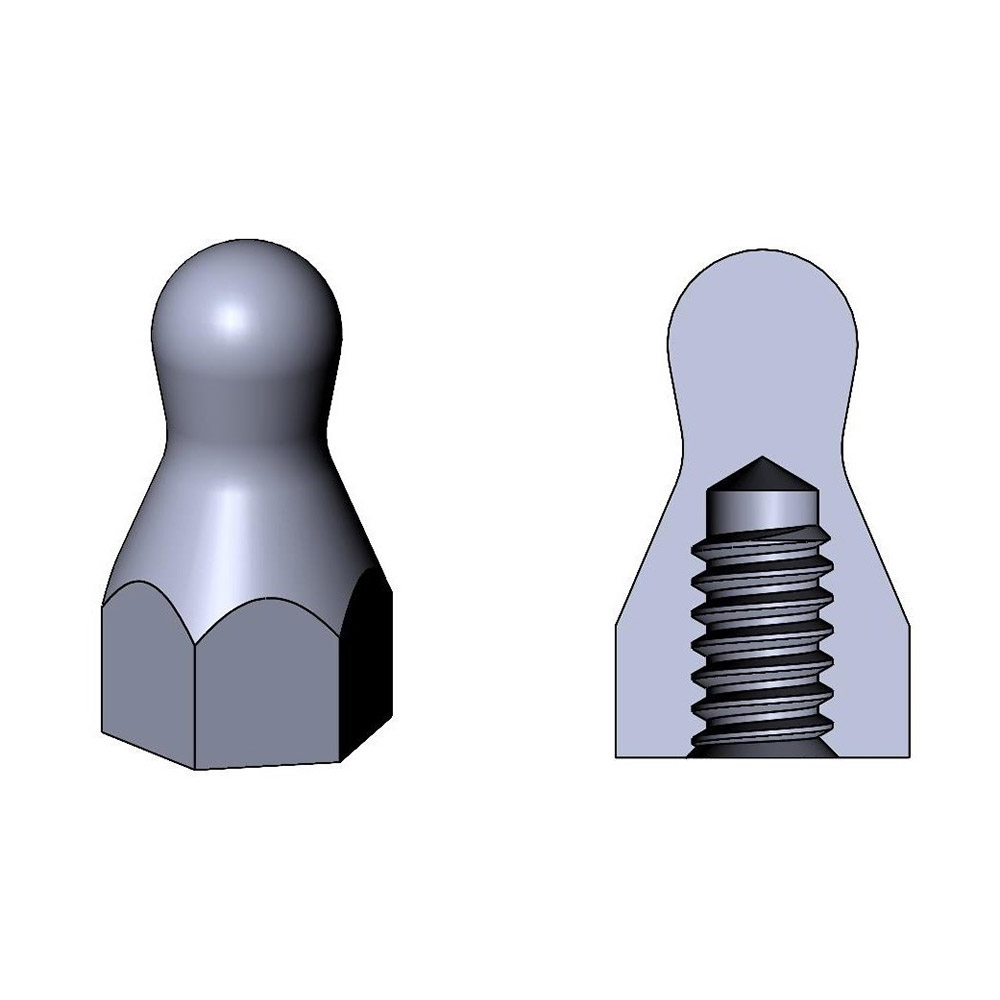

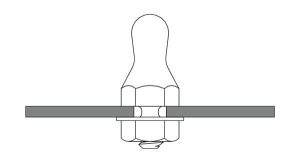

One of the earliest products PENCOM manufactured, ball studs, are still an important product line. PENCOM’s ball studs have an undercut behind the thread ensuring that the part will seat flush in any female mating thread. This feature has made PENCOM’s parts favored over other standard ball studs. Offered in both steel and stainless steel, distributors and design engineers use PENCOM as their source.

About PENCOM’s Ball Studs and Clips

Features

- A convenient spring catch fastener for cabinet doors, inspection panels, etc. requiring repeated disengagement.

- No direct contact between panel surfaces eliminates damaged panel finishes.

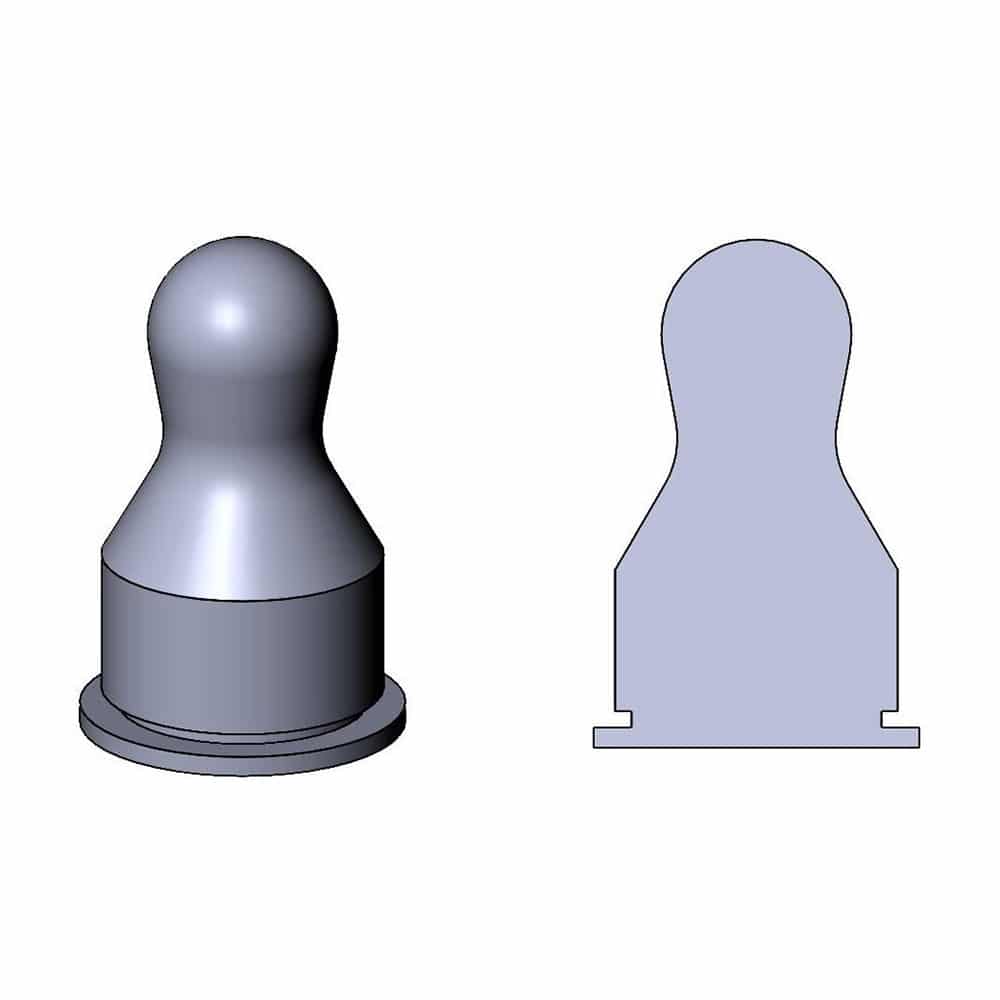

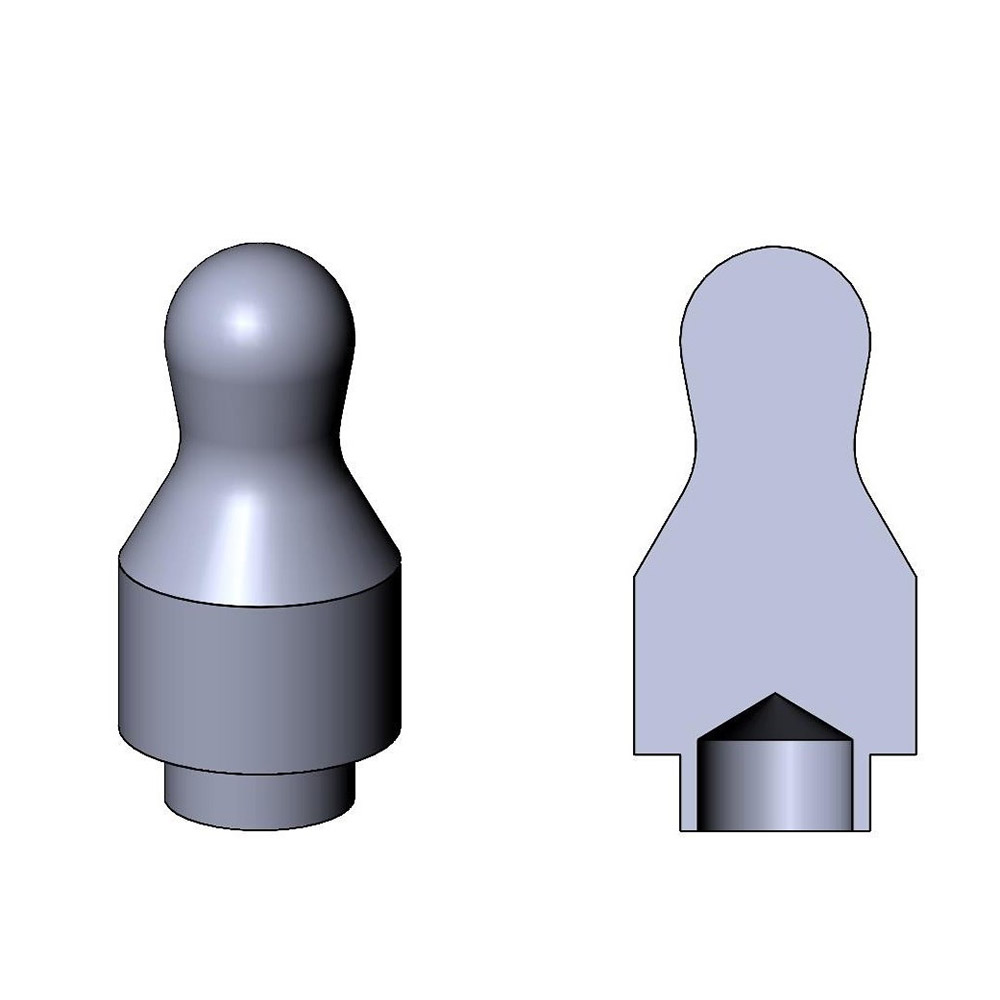

- Accommodate different panel thicknesses by varying ball stud lengths.

- Vary ball stud pull–out tension by using different clip material thicknesses.

- Ball studs and clips available in RoHS-compliant plated carbon steel and stainless steel.

Application Guide

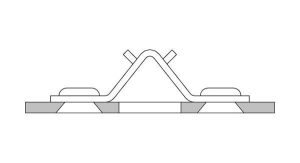

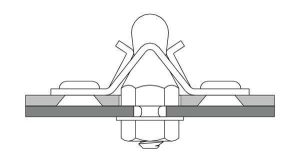

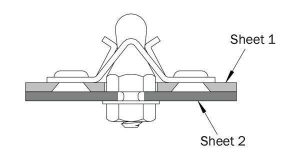

Rivet the ball stud clip onto the panel with either plain or 100° countersunk head rivets, or with screws, nuts and washers (plain rivets shown)

Selection Guide

- Choose a ball stud clip based on the mounting hole diameter, pull–out tension, material, and finish. All clips fit all ball studs. Pull–out tension varies according to the clip material thickness.

- Select a ball stud type from the installation styles below. Go to the appropriate page and choose a ball stud based on length, material and finish. Vary ball stud length to accommodate Sheet 1 thickness.